Revolutionizing Efficiency in the Rolling Mill Industry

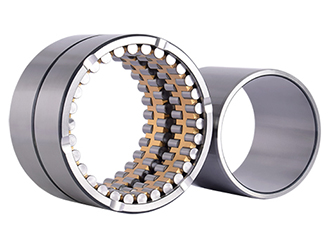

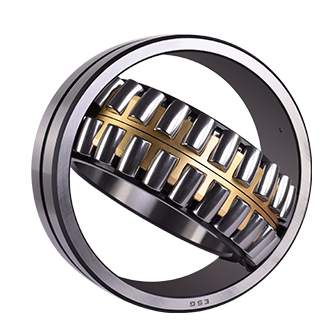

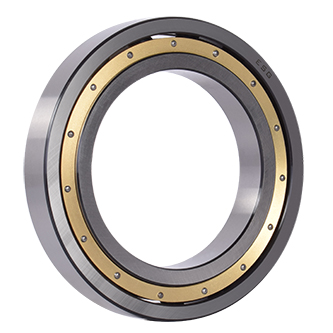

At ESG Bearing, we are dedicated to enhancing efficiency and driving down costs for rolling mills across the industry. Our latest shipment marks another milestone in our journey to provide top-notch solutions that keep the wheels of industry turning smoothly.

Delivering Excellence

In our recent collaboration with a leading steel mill group, we successfully delivered a large shipment of essential rolling mill bearings. This partnership underscores our commitment to supporting the rolling mill industry with reliable and efficient logistics solutions. Each delivery is a testament to our precision, dedication, and the trust our clients place in us.

Innovation at the Core

ESG Bearing continuously innovates our methods and technologies to stay ahead in the industry. From state-of-the-art tracking systems to streamlined delivery processes, we ensure that every step is executed with utmost precision. This commitment to innovation translates into tangible benefits for our clients, allowing them to focus on their core operations while we handle the logistics.

At ESG Bearing, we believe that efficiency and cost-effectiveness are the cornerstones of a successful rolling mill industry. Our latest delivery is just one example of how we strive to make a positive impact. We look forward to continuing our journey, driving innovation, and supporting the industry with unmatched dedication and expertise.