Choosing between inflatable vs rigid sup boards really comes down to what you want from your time on the water. You might love the freedom to travel light or crave top performance. At Onesun, you get quality, innovation, and options for every skill level. To help you decide, let’s look at the main factors people care about most:

|

Factor

|

Inflatable SUPs

|

Hard Paddle Boards

|

|

Portability

|

Easy to carry and store

|

Bulky and heavy

|

|

Durability

|

Tough, military-grade

|

Needs careful handling

|

|

Safety

|

Softer surface, less risk

|

Harder, more impact

|

|

Performance

|

Versatile in conditions

|

Fast, precise tracking

|

|

Comfort

|

Cushioned deck

|

Can be less forgiving

|

With Onesun sup boards, you get the best materials and thoughtful design, whether you choose inflatable or hard SUP.

Key Takeaways

-

Inflatable SUP boards are portable and easy to store, making them ideal for travelers and those with limited space.

-

Hard paddle boards offer superior speed and tracking, perfect for competitive paddlers and those seeking performance.

-

Safety is enhanced with inflatable boards due to their softer surface, reducing the risk of injury during use.

-

Consider your paddling goals: inflatable boards excel in stability and comfort, while hard boards shine in speed and responsiveness.

-

Onesun provides a range of options for all skill levels, ensuring you find the perfect board for your adventures.

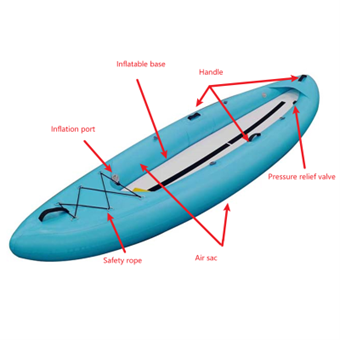

Inflatable SUP Features

Inflatable sup boards, often called isup, have become popular for their convenience and versatility. You can roll up an inflatable paddle board and pack it in your car trunk or closet. This makes inflatable boards perfect for travel or anyone with limited storage space. Onesun uses robust PVC material with an internal drop-stitch design, so our inflatable stand up paddle board models stay lightweight but strong. You’ll find inflatable paddleboards easy to carry, quick to inflate, and surprisingly sturdy on the water. Many paddlers love the softer deck, which feels comfortable underfoot and reduces the risk of scrapes. If you want a board for yoga, family outings, or casual cruising, inflatable sup boards offer stability and flexibility.

Tip: Inflatable boards are great if you want to paddle in different locations or need a board that’s easy to store.

|

Type of Paddle Board

|

Construction Material

|

|

Inflatable SUP

|

PVC construction with drop-stitch core

|

|

Hard Paddle Board

|

EPS foam core with fiberglass or carbon fiber laminate

|

Hard Paddle Board Features

Hard sup boards, also known as rigid paddle boards, deliver a classic paddling experience. You’ll notice the difference in speed and tracking, especially if you’re racing or covering long distances. Hard sup models use foam, fiberglass, or carbon fiber, giving you a board that slices through the water with precision. Rigid paddle boards feel solid and responsive, which appeals to paddlers who want maximum performance. You might prefer a hard paddle board if you have dedicated storage space and want a board that’s always ready to go. Rigid paddle boards suit competitive paddlers, surfers, and anyone who values speed and control.

If you’re deciding between inflatable sup boards and rigid paddle boards, think about where you’ll paddle, how you’ll transport your board, and what kind of experience you want.

Portability & Storage

Inflatable Paddle Boards Portability

If you live in the city or just want to keep things simple, you’ll love how easy it is to move and store inflatable paddle boards. You can deflate your board, roll it up, and fit it into a backpack. This makes spontaneous trips to the lake or beach a breeze. You don’t need a roof rack or a big garage. Onesun’s inflatable paddle boards use lightweight drop stitch material, so you get a sturdy board that’s easy to carry. Most inflatable boards weigh between 18 and 28 pounds, which means you can handle them without breaking a sweat.

Tip: You can store your inflatable in a closet, under your bed, or even in the trunk of your car. It’s perfect for small apartments or anyone who wants to keep their gear out of sight.

Here’s a quick look at how inflatable paddle boards compare to hard boards:

|

Type of Paddle Board

|

Average Weight (lbs)

|

Packed Size

|

|

Inflatable Paddle Boards

|

18–28

|

Can be packed into a backpack

|

|

Hard Paddle Boards

|

24–38

|

Requires more storage space

|

Hard Board Storage

Hard paddle boards give you a classic feel, but you need to plan for storage and transport. These boards stay large and rigid, so you’ll need a dedicated spot in your garage or shed. If you want to take your board to the water, you’ll probably need a roof rack or a trailer. Moving a hard board can be tricky, especially if you live in an apartment or have limited space.

-

Hard boards require careful handling during transport.

-

You need more room to store them, which can be a challenge for city dwellers.

-

They don’t collapse, so you can’t tuck them away in small spaces.

|

Feature

|

Inflatable Paddle Boards

|

Hard Paddle Boards

|

|

Portability

|

Collapse into manageable bags

|

Remain large and rigid

|

|

Storage

|

Can be stored in small spaces like closets

|

Require dedicated storage space

|

|

Transport

|

Often come with wheeled bags and compact pumps

|

Need secure racks and careful loading

|

If you want maximum portability and easy storage, inflatable paddle boards are the way to go. If you have space and want a board that’s always ready, hard boards might suit you better.

SUP Board Performance

When you’re choosing between inflatable vs rigid sup boards, performance is probably at the top of your list. You want a board that matches your style, whether you’re racing, practicing yoga, or heading out with family. At Onesun, we design sup boards for every activity, so you get the most out of your time on the water.

Hard Paddle Board Speed

If speed is your thing, hard paddle boards deliver. You’ll notice the difference as soon as you start paddling. These boards slice through the water with precision, thanks to their foam, fiberglass, or carbon fiber construction. You get superior tracking and glide, which means you can cover more distance with less effort. Here’s what you can expect in competitive racing:

-

Average speed during training: 4.2 MPH

-

Average speed during the race: 5.5 MPH

-

Peak speed achieved: 6.5 MPH

Hard paddle boards excel in sup surfing and racing. The hull design and pointed shape help you maintain direction and speed, even in choppy conditions. Expert reviews say fiberglass paddleboards offer the best tracking, so you stay on course with every stroke. You’ll love the maneuverability and control, especially if you’re chasing performance.

|

Feature

|

Hard Paddle Boards

|

Inflatable SUP Boards

|

|

Tracking Ability

|

Superior tracking due to construction

|

May not maintain the same level of tracking due to flexibility

|

|

Speed and Maneuverability

|

Noted for high performance

|

Stable but less maneuverable

|

|

Hull Design

|

Can have displacement hulls for cutting through waves

|

Generally less efficient in water performance

|

-

Hard paddle boards have finely tuned rails and pointed shapes for better tracking.

-

Inflatable boards tend to flex with each stroke, which can affect tracking.

Inflatable SUP Stability

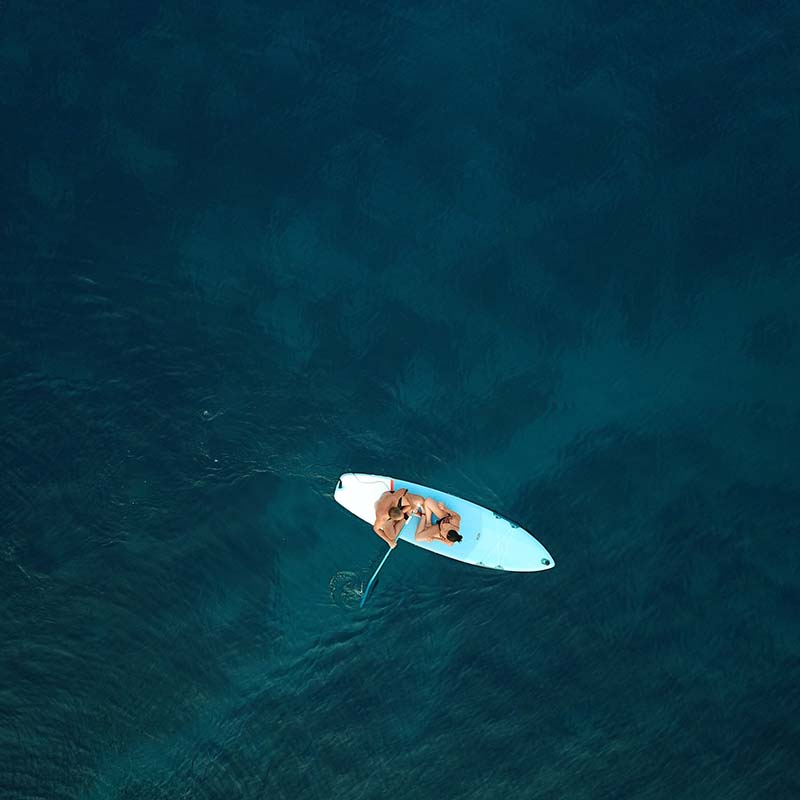

If you want stability, inflatable stand up paddle boards stand out. Onesun’s is up models use a wider design, which gives you a solid, buoyant platform. You’ll feel confident practicing yoga or paddling with kids. Inflatable paddle boards more stable than hard boards, especially for beginners and family outings. The softer deck adds comfort, and you get excellent buoyancy.

|

Feature

|

Inflatable SUP Boards

|

Hard Paddle Boards

|

|

Stability

|

Excellent stability due to wider design

|

Less stable, especially for beginners

|

|

Buoyancy

|

More buoyant platform

|

Standard buoyancy

|

|

Ideal for

|

Yoga, family activities, beginners

|

Performance and speed

|

You’ll find inflatable paddle boards better for activities where balance matters. The pros include comfort, safety, and versatility. The cons? You might not get the same tracking as a hard board, but for most recreational paddlers, stability wins.

Activity Suitability

Different activities call for different sup boards. Onesun offers specialized models for every adventure. Let’s break down the pros and cons for each type:

-

Touring: Hard paddle boards shine with speed and efficiency. You’ll love them for long-distance paddling.

-

Yoga and family fun: Inflatable sup boards provide stability and comfort. You get a forgiving platform for group outings or exercise.

-

All-around use: Isup boards offer versatility. You can use them for casual paddling, exploring, or even sup surfing.

-

Racing: Hard boards give you the edge in speed and tracking. You’ll see the difference in competitive events.

Here’s a quick look at how performance metrics stack up for different board types:

|

Feature

|

Touring Paddle Board

|

All-Around Paddle Board

|

|

Primary Goal

|

Speed and efficiency

|

Stability and versatility

|

|

Shape

|

Longer and narrower

|

Shorter and wider

|

|

Best For

|

Long-distance paddling

|

Beginners and family fun

|

|

Performance in Chop

|

Cuts through effectively

|

More stable but less nimble

|

|

Speed

|

Faster

|

Slower

|

|

Maneuverability

|

Less nimble

|

Highly maneuverable

|

-

Board length affects speed and maneuverability. Longer boards go faster, but they’re harder to turn.

-

Board width influences stability and speed. Wider boards are stable, but slower.

-

Board material impacts performance and durability. Foam, fiberglass, and carbon fiber are common for hard boards.

-

Paddle length and blade size matter for speed and efficiency.

Performance metrics for sup boards include glide, stability, maneuverability, ease of transport, and quality of construction. Here’s how they’re weighted:

|

Metric

|

Weighting

|

|

Glide Performance

|

35%

|

|

Stability

|

25%

|

|

Maneuverability

|

15%

|

|

Ease of Transport

|

15%

|

|

Quality of Construction

|

10%

|

Tip: If you want a board that’s easy to carry and store, go with isup. If you want top speed and tracking, hard paddle boards are your best bet.

When you look at the pros and cons, you’ll see that inflatable paddle boards offer unmatched portability and stability. Hard boards deliver speed and tracking for those who want performance.

Durability & Maintenance

Inflatable SUP Care

Inflatable sup boards, or isup, offer impressive toughness thanks to advanced drop-stitch technology and military-grade PVC. Onesun’s inflatable paddle board models include a double chamber safety feature, so you paddle with confidence even if you encounter a leak. You get peace of mind knowing your isup won’t sink if one chamber loses air.

You might wonder what can damage an inflatable. Here are the most common issues:

You can keep your inflatable sup in top shape with a few simple habits:

-

Rinse your isup with fresh water after ocean paddling.

-

Dry it thoroughly before packing to avoid mold.

-

Don’t roll it up too tightly. This reduces stress on seams.

-

Store your inflatable in a cool, dry place out of direct sunlight.

-

Avoid dragging your isup on gravel or rocks.

-

Watch out for barnacles near docks.

-

Use a 303 protectant to shield against UV rays and stains.

You get a board that’s easy to maintain and ready for adventure. Onesun’s inflatable sup boards combine safety, durability, and convenience, so you spend less time worrying and more time enjoying the water.

Price & Value

Cost Comparison

When you start shopping for a sup board, price often plays a big role in your decision. You’ll notice that inflatable sup boards usually cost less than hard boards. Onesun offers a range of isup models, so you can find something that fits your budget and paddling style.

You get more options with inflatable boards, and many packages include accessories like paddles, pumps, and bags. Onesun’s commitment to quality means you get durable materials and thoughtful design, no matter which board you choose.

Tip: If you want to get on the water without spending a fortune, an inflatable isup package offers great value.

Long-Term Value

Price isn’t the only thing to consider. You want a board that lasts and fits your lifestyle. Hard boards are known for their durability, but they need careful storage and handling. Inflatable sup boards offer easy storage and portability, which makes them perfect for travelers or anyone with limited space.

Let’s look at maintenance over five years:

|

Board Type

|

Maintenance Cost & Repair Process

|

|

Inflatable SUP

|

Requires vinyl repair glue for punctures; can be tricky for some users.

|

|

Hard Paddle Board

|

Easier to repair surface damage; resin fixes cracks with a simple process.

|

|

Degradation

|

Both types degrade with sun exposure; inflatables may have seam issues, hard boards can discolor.

|

You’ll find that isup boards are lightweight and easy to move, saving you time and hassle. Hard boards deliver better speed and responsiveness, which appeals to performance-focused paddlers. Onesun uses premium materials in every board, so you get long-lasting value whether you pick an inflatable or a hard board.

-

Durability matters for long-term value.

-

Storage convenience helps if you live in a small space.

-

Portability makes travel easier.

-

Pricing favors inflatable sup boards for budget-conscious buyers.

-

Performance gives hard boards an edge for racing and advanced paddling.

With Onesun, you invest in quality and innovation. You get a sup board that matches your needs and delivers value for years.

Safety & Ease of Use

Inflatable SUP Safety

When you step onto an inflatable sup, you get a board designed with safety in mind. Onesun’s double chamber inflatable boards give you extra peace of mind. If one chamber loses air, the other keeps you afloat. You can paddle with confidence, knowing your board won’t sink. The military-grade PVC construction stands up to bumps and minor punctures. The softer deck cushions your feet and reduces the risk of scrapes or bruises. You’ll find repair kits included, so you can fix small issues right on the spot.

Here’s a quick look at how inflatable sup boards compare to hard paddle boards for safety:

|

Feature

|

Inflatable SUP Boards

|

Hard Paddle Boards

|

|

Durability

|

Military-grade PVC, resists punctures

|

Prone to dings and cracks

|

|

Stability

|

Wider design, better buoyancy

|

Varies, often less stable

|

|

Impact Safety

|

Softer deck, less risk of injury

|

Hard surface, more impact

|

|

Repairability

|

On-the-go repair kits

|

Repairs can be difficult

|

Tip: If you’re paddling with kids or trying SUP yoga, inflatable boards offer a safer, more forgiving platform.

Hard Board User Experience

Hard paddle boards deliver a classic feel, but you may face a few challenges, especially if you’re new to the sport. Beginners often struggle with storage and transport. You need more space and effort to move a hard board. There’s also a fear of damaging the board, since chips and cracks can happen with rough handling. Repairs for hard boards can be costly and time-consuming.

Families and beginners usually find inflatable boards easier to use. You can deflate and pack them into a compact size, making them simple to carry and store. Inflatable boards feel less intimidating, especially for group activities. You get more stability and comfort, which helps everyone enjoy their time on the water.

-

Hard boards require careful handling.

-

Inflatable boards suit all ages and skill levels.

-

You spend less time worrying about damage with an inflatable.

If you want a board that’s easy for everyone to use, inflatable sup boards are a great choice. Onesun’s commitment to safety and user-friendly design means you can focus on having fun.

Recommendations

Choosing the best sup boards can feel overwhelming. You want a board that matches your lifestyle, skill level, and paddling goals. At Onesun, we design every model with your experience in mind. Let’s break down our top picks for different needs and help you find your best sup.

Best SUP Boards For Beginners

If you’re new to paddleboarding, you want a board that feels stable and easy to control. Onesun’s All Around inflatable sup boards make learning simple. The wide deck gives you balance, and the soft surface feels comfortable under your feet. You can inflate your isup in minutes and start paddling right away. Beginners love the forgiving nature of inflatable paddle boards. You don’t have to worry about bumps or scrapes. The pros include easy setup, lightweight design, and a stable ride. The cons? You might not get the same speed as a hard board, but stability matters most when you’re starting out.

Tip: Try the Onesun All Around inflatable sup if you want a board that grows with your skills.

|

Model

|

Type

|

Pros

|

Cons

|

|

All Around

|

Inflatable SUP

|

Stable, comfy, easy

|

Less speed than hard

|

|

Classic Hard

|

Hard Board

|

Responsive, durable

|

Heavier, less forgiving

|

Best For Travel

You love to explore new places. You want a board that fits in your car or checks as luggage. Onesun’s isup models make travel easy. You can deflate your inflatable paddle boards, roll them up, and pack them in a backpack. The lightweight drop stitch material means you carry your board without effort. You don’t need a roof rack or extra storage. The best sup for travel is the Yoga Inflatable Board or the Double Chamber Inflatable Stand Up Paddle Board. Both offer safety and portability. The pros include compact storage, quick setup, and easy transport. The cons? You might sacrifice a bit of speed compared to hard boards, but convenience wins when you travel often.

Note: If you plan to travel by plane, choose an isup that fits in standard luggage. Onesun’s travel-friendly designs help you paddle anywhere.

|

Model

|

Type

|

Travel Pros

|

Travel Cons

|

|

Yoga Inflatable Board

|

Inflatable SUP

|

Packs small, lightweight

|

Less speed than hard

|

|

Double Chamber Inflatable SUP

|

Inflatable SUP

|

Extra safety, portable

|

Slightly heavier

|

|

Hard Touring Board

|

Hard Board

|

Fast, efficient

|

Bulky, hard to pack

|

Best For Performance

You want speed, precision, and control. You crave the thrill of racing or touring long distances. Onesun’s Dazzle Elongated Competition SUP Board stands out as the best sup for performance. Hard boards deliver unmatched glide and tracking. You feel every stroke propel you forward. The pros include top speed, responsive handling, and a classic paddling feel. The cons? Hard boards require more storage and careful transport. If you want the best sup for racing, choose a hard board. If you want versatility, consider a performance isup for mixed activities.

Tip: For competitive paddlers, hard boards offer the edge you need. Onesun’s Dazzle Competition model combines speed and style.

|

Model

|

Type

|

Performance Pros

|

Performance Cons

|

|

Dazzle Competition SUP

|

Hard Board

|

Fast, precise, responsive

|

Needs storage, less portable

|

|

Performance Inflatable SUP

|

Inflatable SUP

|

Versatile, stable

|

Not as fast as hard

|

Best For Families

Family outings call for stability, safety, and fun. Onesun’s Large Tandem SUP Paddle Board is the best sup for families. You can paddle with a friend or child and share the adventure. Inflatable sup boards give you a soft, stable platform. You don’t worry about bumps or falls. The pros include extra space, comfort, and easy setup. The cons? Tandem boards can be heavier than solo models, but you get more room for everyone. Hard boards work for families too, but inflatable paddle boards offer more safety and convenience.

Tip: Choose a tandem isup for group outings. Onesun’s family-friendly designs make every trip memorable.

|

Model

|

Type

|

Family Pros

|

Family Cons

|

|

Large Tandem SUP

|

Inflatable SUP

|

Roomy, stable, safe

|

Heavier than solo

|

|

All Around SUP

|

Inflatable SUP

|

Easy for kids, comfy

|

Less speed than hard

|

|

Hard Family Board

|

Hard Board

|

Durable, classic feel

|

Needs more storage

|

Quick Recommendation Table

|

Use Case

|

Best SUP Model

|

Type

|

Why It’s Best

|

|

Beginners

|

All Around Inflatable SUP

|

Inflatable SUP

|

Stable, easy, forgiving

|

|

Travel

|

Yoga Inflatable Board / Double Chamber

|

Inflatable SUP

|

Packs small, lightweight

|

|

Performance

|

Dazzle Competition SUP

|

Hard Board

|

Fast, precise, responsive

|

|

Families

|

Large Tandem SUP

|

Inflatable SUP

|

Roomy, safe, stable

|

You want the best sup for your lifestyle. Onesun offers sup boards for every adventure. Whether you choose isup or hard boards, you get quality, innovation, and a board that fits your needs. Explore our collection and find your perfect paddleboards today.

Choosing between inflatable and hard sup boards comes down to what you want from your paddling experience. Inflatable boards make storage and travel easy, while hard boards deliver speed and control for racing or surfing. Take a look at the table below to see how each type stacks up:

|

Feature

|

Inflatable SUP Boards

|

Hard Paddle Boards

|

|

Portability

|

Lightweight, easy to store

|

Bulky, needs more space

|

|

Performance

|

Stable, beginner-friendly

|

Fast, precise tracking

|

You know your goals best. Explore Onesun’s collection and find the board that fits your lifestyle and adventure.

FAQ

How long does it take to inflate an Onesun inflatable SUP board?

You can inflate most Onesun inflatable SUP boards in about 5 to 10 minutes with a manual pump. Electric pumps make the process even faster. You’ll be ready to hit the water in no time.

Can I use an inflatable SUP board for yoga or fitness?

Absolutely! Onesun’s Yoga Inflatable Board features a wide, stable platform. You get plenty of space for poses and exercises. The soft deck feels comfortable, so you can focus on your workout.

What’s the best way to store my SUP board?

You should rinse your board with fresh water and let it dry completely. Store your inflatable SUP in a cool, dry place. Hard boards do best on padded racks indoors. This keeps your board in top shape.

Are Onesun SUP boards suitable for beginners?

Yes! Onesun designs boards for all skill levels. You’ll find the All Around Inflatable SUP easy to balance and control. Beginners love the stability and comfort. You can start paddling with confidence.

Do Onesun SUP boards come with a warranty?

Yes, you get a warranty with every Onesun SUP board. We stand behind our products and offer support if you have any issues. You can contact our team for details or help.