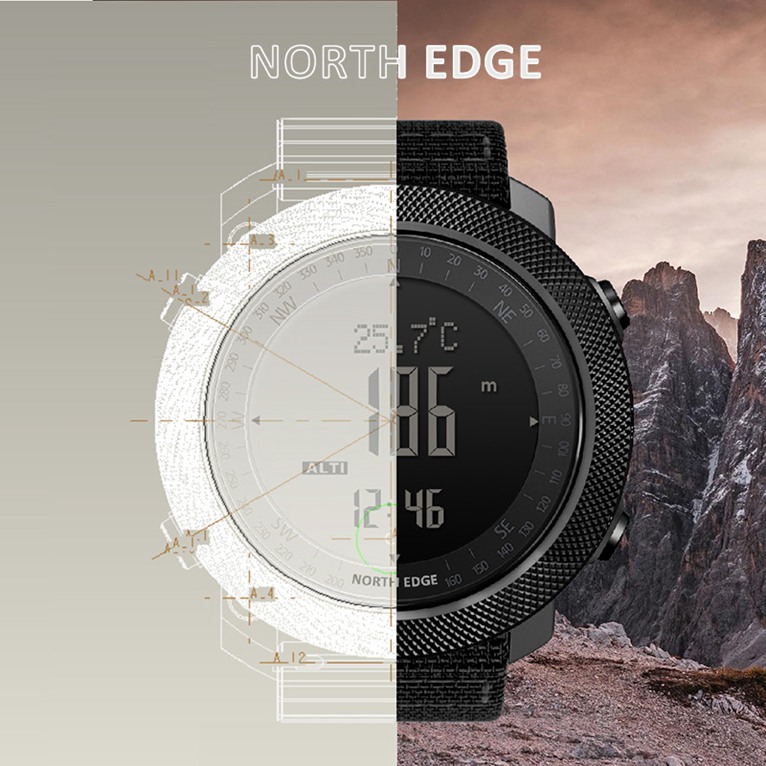

Explore the Depths with NORTH EDGE Cutting-Edge AQUA !

Explore the Depths with NORTH EDGE Cutting-Edge AQUA !

Do you have an adventurous spirit yearns to explore the mysteries of the deep blue sea? Look no further than the remarkable dive watch by North Edge! Crafted with precision and built to withstand the demands of the underwater world, our dive watch is the ultimate companion for underwater enthusiasts. With an array of features and functions that cater to both free diving and scuba diving, it's time to into a world of limitless exploration.

North Edge AQUA goes beyond just underwater timekeeping. Whether you're a free diver or a scuba enthusiast, our watch is designed to elevate your underwater experience. With features like NDL time, depth and temperature indicators, and diving speed measurements, you can monitor and track your underwater adventures effortlessly.

North Edge AQUA is crafted to endure the toughest conditions. With a remarkable water resistance of up to 100 meters, it is built to accompany you on all your aquatic endeavors. Dive with peace of mind, knowing that your watch is up to the challenge, no matter how far you venture into the depths.

North Edge AQUA isn't just about diving. It comes packed with an array of useful functions that add value to your everyday life. Stay on track with alarm, date, and time settings. Measure your achievements with the stopwatch and countdown features. Illuminate your surroundings with the built-in backlight. Our dive watch is not just a timepiece; it's a reliable companion both above and below the surface.

Dive into a world of adventure with our cutting-edge dive watch. Designed for explorers, our watch combines functionality, reliability, and resilience to provide the ultimate underwater experience. Whether you're a free diver, a scuba enthusiast, or simply an adventure seeker, our dive watch is the perfect companion for your aquatic endeavors. Embrace the thrill of exploration and trust in North Edge to take you to new depths.